(1)the base has reached the necessary curing time and strength, and the time of the cast-in-place concrete curing shall not be less than 28 days under favorable climatic conditions (such as summer) and not less than 60 non-frozen days under unfavorable conditions (such as winter) ;

(2)when the layered construction, the plaster layer should be completely cured and to achieve the necessary strength;

(3)no cracks in the masonry and the gap between the insulation board (except structural joints) are not more than 5mm;

(4)before the outer wall and roof inside the plaster to ensure that the insulation layer and the waterproof layer has been installed in place, and through the condensation test to avoid dew point in the paint layer;

(5)windows have been installed in place or have measures to ensure that the room is not rain and other environmental factors erosion;

(6)at the grassroots level and buried pipeline and other work has been completed;

(7)The indoor air temperature shall not be less than 5 ° C during the construction period and after 24 hours.

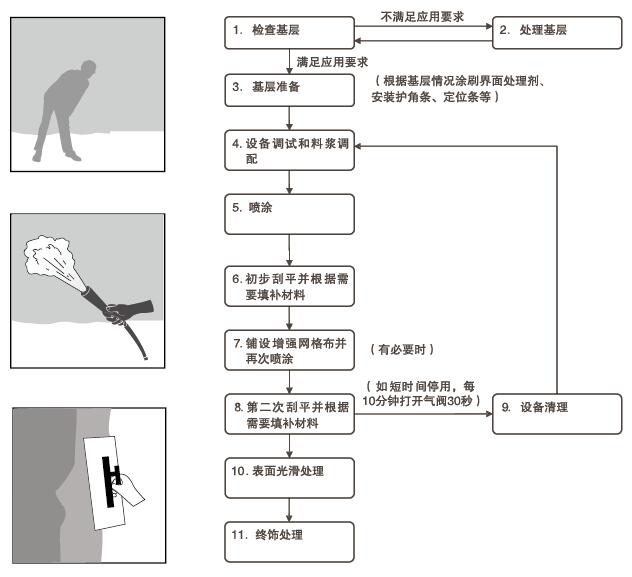

Behoft construction of the high-end indoor plastering system shall be carried out according to the following procedures and procedures

Behoft Spraying Gypsum System can be used for almost all common base materials including but not limited to cast-in-place concrete, concrete prefabricated boards, clay bricks, perforated bricks, aerated concrete, lightweight blocks, lime bricks, plaster Board, organic insulation sheet, the existing plastering materials, and so on.

In order to achieve a durable plaster effect, the use of the table before the requirements and methods to the grassroots for careful inspection and processing.

| Grass - roots inspection, requirements and treatment | |||

|---|---|---|---|

| Check item | Inspection Method | Claim | Approach |

| Grassroots ruggedness | With a knife to scratch, with steel hammer percussion, naked eye observation | There should be no weathering, the width of more than 0.2mm cracks, hollowing and loosening and so on | Use a steel brush or steel hammer to remove non-rigid parts. Fissures with a width greater than 0.2mm are filled with suitable grouting material |

| Surface residual release agent or curing agent (only for concrete base) | Brush test (if the surface of the hydrophobic phenomenon that may have a residual release agent or curing agent) | There should be no residual release agent or curing agent | With the appropriate cleaning agent cleaning, high pressure sandblasting treatment |

| Surface attachments | Wipe, naked eye | There should not be any foreign matter, paint, wallpaper, pan base, mud, lime and so on | With a steel brush or blade scraping, high pressure sandblasting |

| surface temperature | thermometer | Not less than 5℃ | Room heating and heating |

| Moisture content (only for concrete base) | With concrete CM instrument | The moisture content of concrete base shall not be greater than 3% | And other concrete fully dry and then construction |

| Flatness | 2m by foot, steel ruler | 2m range of any direction of flatness deviation of not more than 15mm | With the appropriate material for leveling treatment, and so it is completely dry and then construction |

| Depth of more than 15mm gap and void | Visual observation, ruler measurement | The width of the voids other than the structural joints and the void diameter shall not exceed 5 mm | Fill with the appropriate material, and so on after the full dry and then construction |