| project | Bitton gypsum wall | Cement mortar wall |

|---|---|---|

| Construction speed | 300-500㎡/group.day | 150-200㎡/group.day |

| Conservation cycle | 4 hours to reach 90% strength | 7 days |

| Construction Quality | No hollowing, cracking phenomenon | Easy to hollow, crack |

| 14 days shrinkage | 0.038% | 0.285% |

| Thermal Conductivity | 0.35w/m.k | 0.93w/m.k |

| PH value | 7 (neutral) | 11-13 (partial alkaline) |

| 30mm plastering | Once done | Layered construction |

| Average thickness | 8-20mm | 20-30mm |

| Unit area usage | 8-20kg | 40-60kg |

| Water retention rate | 80% | 45% |

| Water storage capacity | 7-17g/㎡ | 6-9g/㎡ |

| Water vapor through resistance | 10 | 15-35 |

Behoft gypsum does not contain heavy metal oxides and does not release any radiation harmful substances. With the human skin similar to the PH value of nearly 7 (cement mortar is about 11-12, alkaline), can inhibit the growth of mold, gypsum in the decoration of the room, the bacteria difficult to survive and spread. Do not stimulate and damage the skin, do not produce allergies, healthy and friendly.

Behoft gypsum with biological solubility, inhalation of the body of the plaster will be absorbed by the body, does not affect the health. The bio-solubility of gypsum is 2.5 g / L, limestone is 0.3 g / L, Silica sand will not be absorbed by the body. If the inhalation of cement will seriously affect health. Europe allows the human body to be exposed to gypsum dust for a limit of 8 hours 6mg / m3.

Behoft gypsum has excellent fire resistance, Is a safe building material, is not combustible A1 grade (GB 8624-2006) inorganic material. As the gypsum crystal contains 21% of the crystal water, when the fire occurs, the first evaporation of crystal water, Absorb a lot of heat. Only after all the decomposition of crystal water is completed, the temperature can be on the basis of 100 ℃ on the basis of continued to rise, and in its decomposition process generated a large number of water vapor screen, But also the spread of the flame plays a barrier role, there is no toxic smoke generated, which for the escape of fire to win the prime time and to prevent the protection of components prematurely heated.

Gypsum industry manufacturing energy consumption is much lower than the cement industry, construction gypsum per kilogram of energy consumption of about 960 ~ 1460kJ, only cement 1/4, lime 1/3. Building gypsum investment less production capacity, simple process, easy to large-scale production. Production energy consumption than the cement savings of 78%, can save a lot of valuable non-renewable energy.

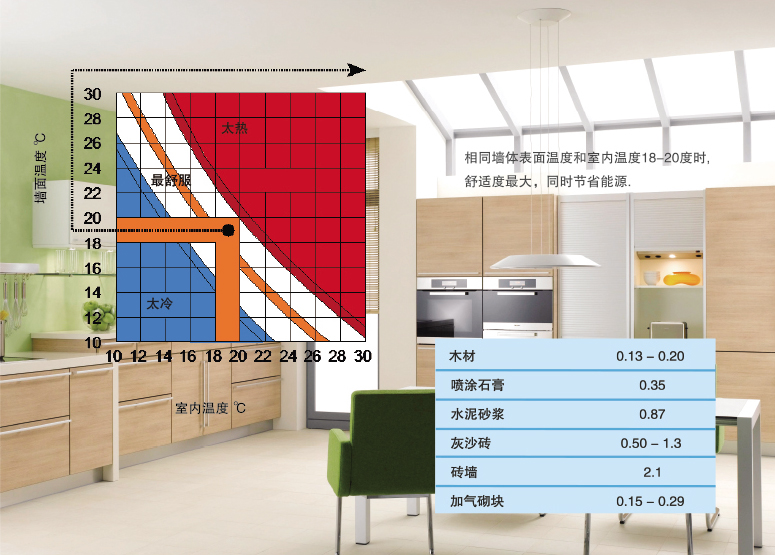

Gypsum material itself, the thermal conductivity of 0.20~0.28W / (m.K) ,about 13.3% to 17.2% of cement concrete, clay brick 24.7%~ 32.1%。 Under the same conditions, the main factors that determine the level of thermal conductivity also include the porosity of the product. Its hydration hardening body is a porous material, not only has good insulation properties, but also has excellent thermal insulation properties. Gypsum wall than the cement wall has a better insulation, heat insulation, in use can effectively reduce building energy consumption.

As we all know, building energy consumption accounts for 40% of the total energy consumption, Energy conservation in the building there is still a great potential for development. Gypsum as a kind of energy-saving building materials, by more and more attention, its application in the construction area with the progress of science and technology gradually expanded, Gypsum is in its own advantage to help people build more and better energy-saving buildings.

Carbon emissions are a global hot issue, producing 1 ton of cement to about 1 ton of carbon dioxide emissions, but the production of 1 ton of gypsum powder only emissions of 0.14 tons of carbon dioxide. Due to light, efficient, transport, construction of carbon emissions during the process is also very low. According to the results of the assessment, in terms of energy consumption plaster is only cement 1/4, carbon dioxide emissions only cement 1/10, Freon emissions only 1/14 of the cement, sulfur dioxide emissions only 1/20 of the cement. Gypsum is very low carbon footprint, reduce carbon dioxide emissions, reduce greenhouse effect. Reduce sulfur dioxide emissions, reduce acid rain.

Gypsum building materials is a kind of energy saving, recyclable, do not pollute the environment, the advantages of superior quality green building materials. First of all, the production of gypsum materials in the raw materials do not add any toxic and harmful raw materials. Second, the gypsum building materials are dihydrate gypsum from the low temperature calcination, hydration and then become dihydrate gypsum reversible cycle. Again, gypsum building materials not only in the production process does not emit emissions, waste residue, waste water and harmful substances on the human body, in the construction process no noise, no smell, in the course of the use of non-toxic harmless. Finally, the abandoned gypsum building materials, broken, screened, and then calcined after the gypsum as a raw material for the production of gypsum, does not produce construction waste, is a typical recyclable recycling of environmentally friendly materials.

Gypsum due to the production and use of various greenhouse gas emissions are low, 100% recyclable, economical, friendly to human health, Has been recognized as the construction of three cementitious materials that cement, lime, gypsum, the best performance of the best building materials.

Behoft spray gypsum has a strong adhesive force. Almost with a variety of substrates can be well bonded. Gypsum slurry into the wall of the gap. In hydration hardening. (0.05% to 0.15%), the expansion of the water hardening of the physical wedge adhesion, so that the wall is not firmly bonded to the hollow drum. After the hardening of the thermal expansion and contraction rate and wet shrinkage shrinkage is also very small (less than 0.1%, usually 15m long without expansion joints). Its crystal water and micro-pore structure. Almost no external hot and cold affected. Dimensional stability. So you can make sure your walls are not hollowed out and not cracked.

Pleasant’s spray gypsum does not divide the bottom layer and the surface layer, once wiped 8mm to 30mm thickness, single layer can reach the smooth surface. Using machine spraying construction,

Five people with a machine can be completed one day 300 square meters to 500 square meters of plastering the wall, the efficiency of at least three times the traditional artificial plaster. Its excellent operability, even if the artificial plaster,

Construction efficiency is twice the traditional plastering.

Behoft spray gypsum hydration fastening, the strength to enhance the rapid, without conservation. The waiting time before finishing is only half of the traditional cement mortar plaster,

Can greatly improve the efficiency, so that the project ahead of operation.

Behoft spray gypsum hydration hardening after the hole-like structure, many of the pores make the wall with a "breathing" function. When the ambient humidity is large, the breathing hole automatically absorbs,

In the opposite conditions, can automatically release the reserves of water, so repeated cycle, cleverly control the indoor humidity within the appropriate range. Behoft product unique recipe perfect way to release this feature, creating a comfortable climate with a humidity of 40% - 60%.

Wood is the most popular indoor building materials,

Because it’s warm, make people feel warm and comfortable. Spraying gypsum has similar to the wood "warm", the thermal conductivity and wood similar to the warm,

Can play the role of Dongnuanxialiang, improve human comfort. The "breath" and "warm" properties of the Pompid Spray Gypsum can be effectively adjusted for ambient temperature and humidity,

To create a comfortable livable environment.

Behoft plastering gypsum has excellent breathing function, indoor humidity can absorb excess moisture, when the room is too dry when the release of moisture, effectively adjust the indoor humidity, to achieve a comfortable living environment